AC1000S

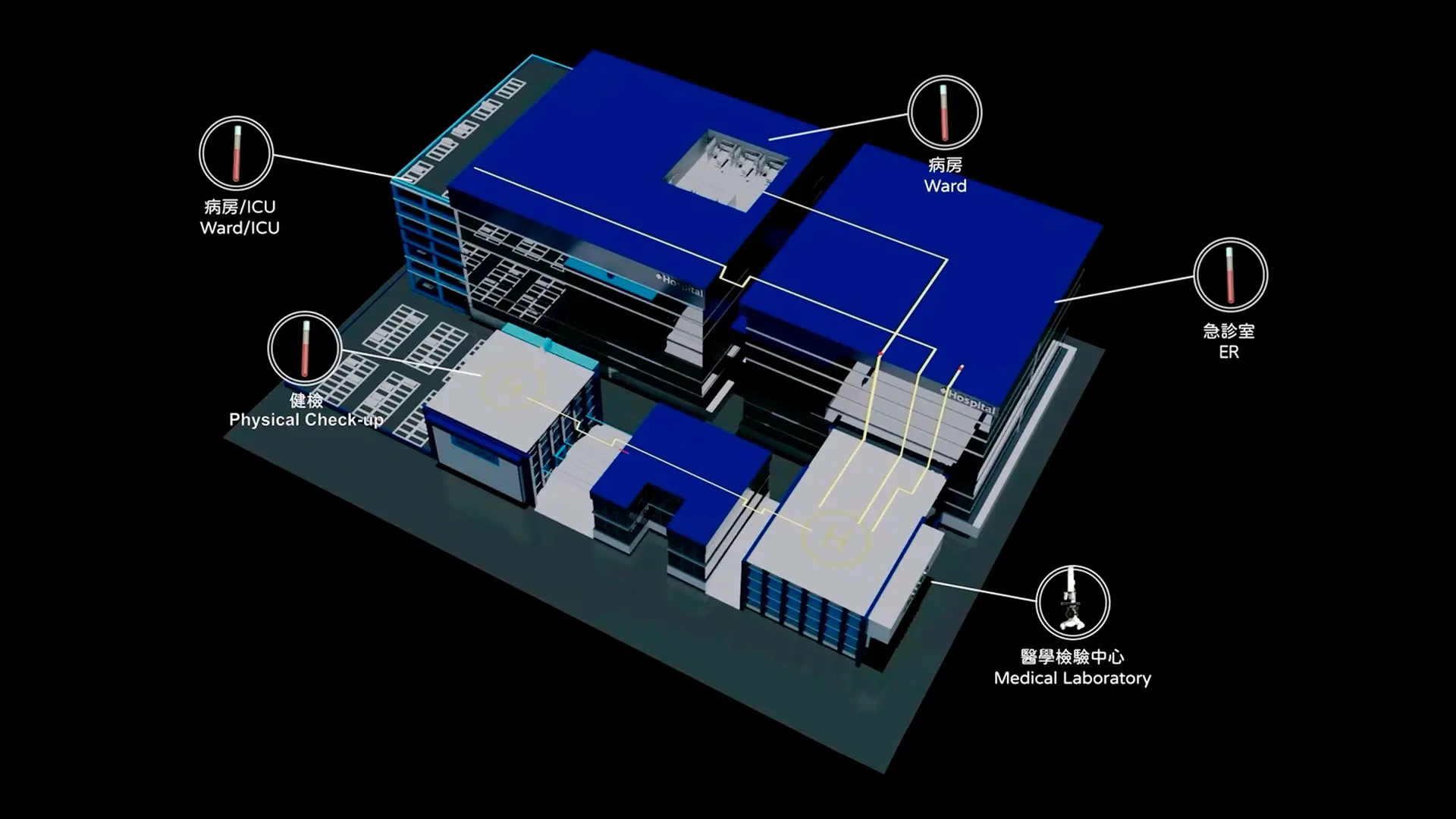

Pneumatic Vacutainer Delivery System Model S

1.Depth/Width/Height : 700×750×1700 mm

2.Transport speed:600~1200 pcs/hrs (100 meters of continuous input, can be adjusted according to parameter settings)

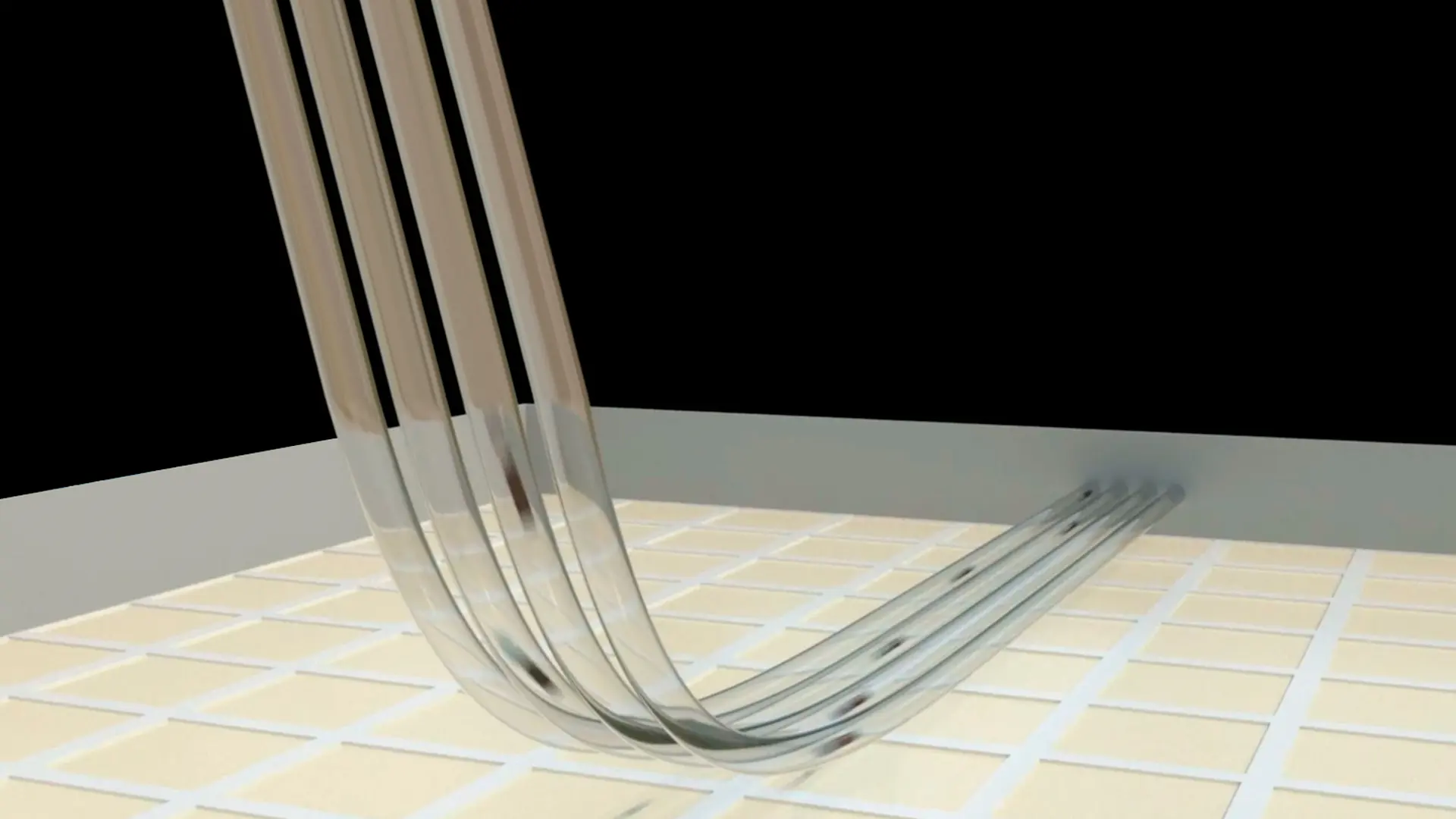

3.Transfer pipe size:(outer diameter)22mm,(inner diameter)19mm

4.Test tubes available : (Total length)70~110mm /11-17mm

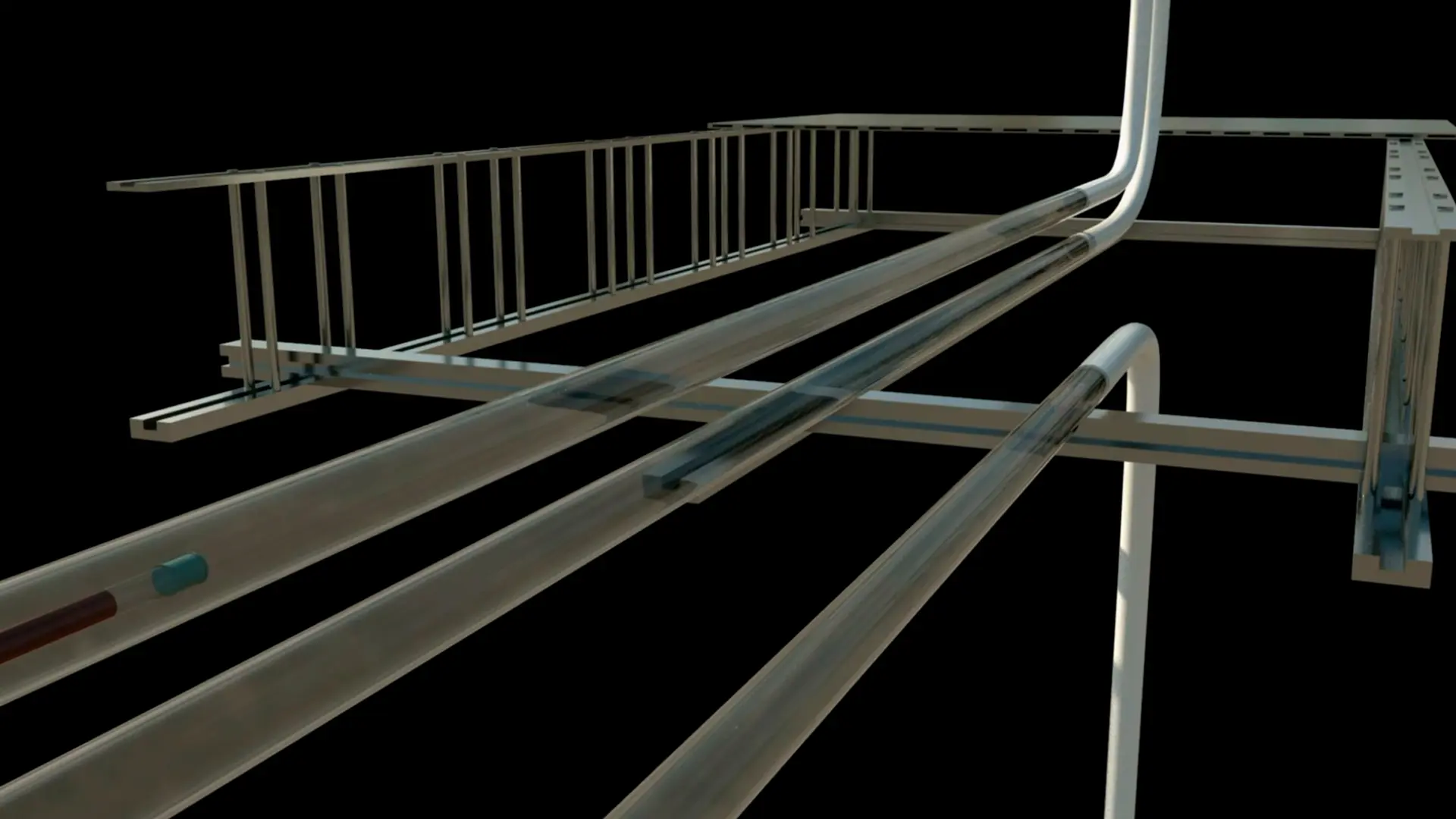

5.Pipe length: up to 800 meters

6.Transmission pipeline: 1~4 multi-point transmission, 3 pipelines + 1 return box or 4 transmission pipelines (according to customer needs)

7.Operating noise level:60-65 dB

8.The input port capacity can reach 250 pieces

9.Computer 15-inch touch panel

10.Electricity: 220V / Single phase power

11.Air pressure: 280L/min (0.8Mpa)

12.Controller: PLC